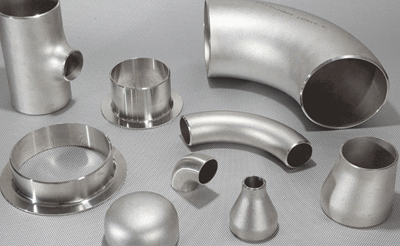

Buttweld Fittings

Buttweld Fitting

Buttweld Fitting accomplish a lot of admiration by our clients owing to its high strength, dimensional correctness, high tension power, corrosion resistant and consistency. These products are used in various commercial, industrial and automobile industries. We manufacture these fittings using high grade of raw material by implementing most ultra modern technology. These products are clients can avail from us at various sizes, shapes and design as per the requirements.

These manufacturer's material expertise is diversified, allowing them to suit the needs of specific industrial situations. Carbon steel fittings (e.g., ASTM A234 WPB) are the most commonly used for moderate-duty and low-temperature applications due to their durability and cost-effectiveness. Manufacturers offer Stainless Steel choices for corrosive situations (grades 304, 316, and 321) that give higher oxidation resistance. Alloy steel fittings (such as WP11, WP22, and WP91) are used in high-pressure or high-temperature applications due to their superior mechanical qualities. Furthermore, specialty Nickel Alloy fittings (such as Monel, Inconel, and Hastelloy) are designed to endure severe heat and corrosion in the most hostile chemical processing or marine conditions.

Top-tier manufacturers set themselves apart with broad supply chains and value-added services that go beyond standard production. Custom fabrication is available from companies like Metallica Metals and American Stainless, enabling non-standard diameters and thicknesses from 1/2" NB to 72" NB and schedules up to XXS. They offer specific surface treatments including hot-dipped galvanizing, electro-polishing, and epoxy coating to increase the longevity of the fittings. These producers service both domestic and foreign markets with strong logistics networks, guaranteeing that premium parts are delivered to infrastructure projects worldwide with 100% radiography testing and independent inspections to ensure safety.

Materials and Grade:

Types:

Seamless and Welded butt weld fittings.

Applicable Standards:

ASME / ANSI B16.9, ASME B16.28, MSS SP-43, EN 10253-1, and EN 10253-2.

Size Range:

½” to 64” (DN 15 to DN 1600).

Wall Thickness:

SCH 10, SCH 20, SCH 30, STD, SCH 40, SCH 60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, and XXS.

Product Range:

Seamless and welded long radius and short radius elbows (90°), long radius elbows (45°), long radius and short radius return bends (180°), reducing elbows, equal and unequal tees, crosses, concentric and eccentric reducers, long and short stub ends, collars, pipe caps, and long radius bends with radii of 3D, 5D, 6D, 8D, 10D, and 20D in 15°, 30°, 60°, and 90°. Drawing-based and customized butt weld fittings are also supplied.

Stainless Steel

ASTM / ASME SA 403 Grade WP “S”, “W”, and “WX” in grades 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, and 347H.

Duplex Steel

ASTM / ASME SA 815 UNS S31803, S32205, S32550, S32750, and S32760.

Carbon Steel

ASTM / ASME A234 WPB and WPC, and ASTM / ASME A860 WPHY 42, WPHY 46, WPHY 52, WPHY 60, WPHY 65, and WPHY 70.

Alloy Steel

ASTM / ASME A234 WP1, WP5, WP9, WP11, WP12, WP22, WP23, and WP91.

Nickel Alloy

ASTM B / SB 163 for Nickel 200 and Nickel 201; ASTM B / SB 163 and 165 for Monel 400; ASTM B / SB 464 for Alloy 20; ASTM B / SB 167 for Inconel 600, 601, and 625; ASTM B / SB 704 and 705 for Incoloy 800, 800H, and 825; and ASTM B / SB 619, 622, and 626 for Hastelloy C22 and Hastelloy C-276.