Products

Forged Flanges

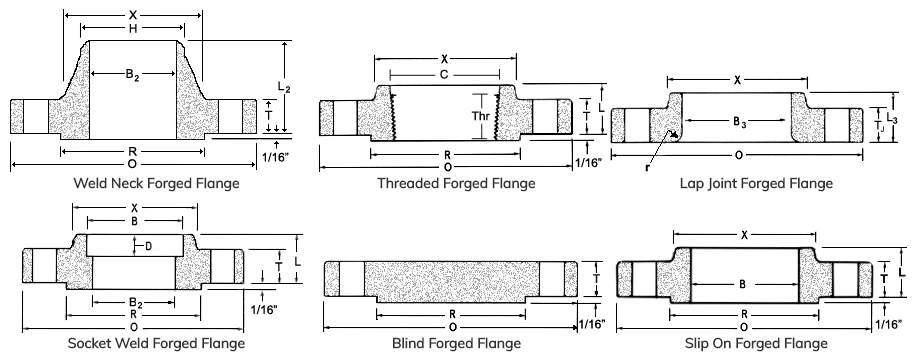

ANSI B16.5 Forged Flanges Manufacturers in Stavanger Stal, Manufacturer &aamp; Suppliers of Forged Flanges, forged flange manufacturers, SS Forged Flanges, Carbon Steel Forged Flanges manufacturer in Norway, Stainless Steel Forged Flanges manufacturer in Norway, Alloy Steel Forged Flanges manufacturer in Norway, Inconel Forged Flanges, Monel Forged Flanges, Hastelloy Forged Flanges in Stavanger Stal & Asia, ANSI B16.5 Forged Flanges exporter in Norway , ANSI/ASME B16.5, B16.47, B16.47, B16.36, B16.48 Forged Flanges,Carbon Steel forged Flanges, Stainless Steel forged Flanges, Alloy

We are largest manufacturers of Forged Flanges , 304 Forged Flanges, 316 Forged Flanges, astm a105 Forged Flanges, astm a182 Forged Flanges as per asme / ansi B16.5 forged flanges, ansi B16.47 forged flanges, Din forged flanges, jis forged flanges & uni forged flanges Standards, Fabricated Forged Flanges, awwa c207 class b forged flange, bs pn16 flange

Best

offer on high quality Forged Flanges in all size, classes & dimensions like Class 150 Forged Flanges, Class 300 Forged Flanges,Class 400 Forged Flanges, Class 600 Forged Flanges, Class 900 Forged Flanges, Class 1500 Forged

Flanges & Class 2500 Forged Flanges

Forged Flanges Specification

| Type | Forged Flanges, ASME 16.5 Forged Flanges |

|---|---|

| Size | 15 NB to 750 NB, 1/2-78 inch (DN15-DN2000) |

| Material | Stainless Steel Forged Flanges: ASTM A182 F202, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 316LN, 310S, 317L, 321, 410, 420, 440C, 202. F904L Carbon Steel Forged Flanges: A-350 LF2 LF3, A105 Duplex Steel Forged Flanges: ASTM / ASME SA 182 F 44 , F 45 , F51 , F 53 , F 55 , F 60 , F 61. Alloy Steel Forged Flanges: ASTM A182 F1, F5, F9, F11, F22, F91 Special Alloy Forged Flanges: Duplex, Super Duplex, Nickel Alloys Nickel Alloy Forged Flanges: Cupro Nickel (90/10, 70/30, 66/30/2/2), Hastelloy (C-4, C-22, C276, B-2), Nickel (200 / 201 / 205), Monel 400 & K500), Inconel (600, 601, 625 & 825), Incolloy (800, 800H), Alloy 20, Duplex Steel, SS 904L, Titanium (1 & 2) Etc. |

| Standard | ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 ,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820 DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S : BS4504 , BS4504, BS1560, BS10 |

| Pressure Class | Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Specialize | As per drawing |

| SIZE RANGE: FLANGES ½” to 36” (10mm to 900mm) | |

|---|---|

| Standards | Types |

| ASME/ANSI B16.5 | Welding Neck Flange, Slipon Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 |

| . | |

| ASME/ANSI B16.47 | Welding Neck Flange, Blind Flange (series A & B) |

| Pressure Class | 75, 150, 300, 400, 600, 900 |

| . | |

| ASME/ANSI B16.36 | (Orifice Flanges) Welding Neck Flange, Slipon Flange, Threaded Flange |

| Pressure Class | 300, 400, 600, 900, 1500, 2500 |

| . | |

| JIS B2220/B2291 | Welding Neck Flange, Slipon Hub Flange, Slipon Plate Flange, Shut off Flange, Square Flange |

| Pressure Class | 5k, 10k, 16k, 20k, 30k |

| . | |

| BS 4504 SEC3.1 | Welding Neck Flange (111/134), Hubbed Slipon Flange (112), HubbedThreaded Flange (113), Lapped Pipe End Flange(133), Plate Flange (101),Loose Plate Flange (102), Loose Plate with Weld Neck Flange (104), Blank Flange (105) |

| Pressure Class | PN 2.5 To PN 40 |

| SIZE RANGE: FLANGES ½” to 36” (10mm to 900mm) | |

| BS 4504(PART.1) | Welding Neck Flange, Hubbed Slip-on Hubbed Threaded, Plate Flange, Loose Plate with Weld on Plate Collar, Blank Flange. |

| Pressure Class | PN2.5 To PN 400 |

| . | |

| BS1560 | Welding Neck Flange, Socket Welding Flange, Slip-on Boss Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 |

| . | |

| BS 10 | Welding Neck Flange, Plate Slip-on Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| Table | D,E,F,H |

| . | |

| DIN FLANGES | DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656,DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638, DIN 2673 |

| Pressure Class | PN6 TO PN 320 |

| . | |

| Pr EN 1092-1 FLANGES | Plate Flange (01), Loose Plate Flange (02,04), Blind Flange (05)Welding Neck Flange (11) Hubbed Slip On Flange (12), Screwed Flange (13), Integral Flange(21) |

| Pressure Class | PN2.5 To PN100 |

| . | |

| ASME/ANSI B16.9/ | |

| MSS SP-4 | Stub End |

| Type | A, B , C |

| PRODUCTION CAPACITY : Forged 5000 MT/p.a. Machined 2000 MT/p.a. | |

ASME/ ANSI B16.5 Forged Flanges Manufacturing Materials :

|

Dimensions

|

Base Material

|

Pressure Rating

|

|---|---|---|

|

ASME B16.5

|

ASTM A182 (Forgings) ASTM A240 (Plate)

|

150#. 300#. 400#. 600#. 900#. 1500#. 2500#.

|

|

API 605

|

ASTM A182 (Forgings) ASTM A240 (Plate)

|

150#. 300#. 400#. 600#. 900#. 1500#. 2500#.

|

|

ASME B16.47series A & B

|

ASTM A182 (Forgings) ASTM A240 (Plate)

|

150#. 300#. 400#. 600#. 900#. 1500#. 2500#.

|

|

EN1092-1

|

ASTM A182 (Forgings)

|

PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400.

|

|

BS4504

|

BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings)

|

PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160.

|

|

BS10

|

BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings)

|

Dimension of Forged Flanges

ANSI B16.5 Forged 1/2″ – 24″ Flange Classes

Ansi B16.5 Class 150 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

TJ

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

D

|

Thr

|

|

½

|

3.50

|

0.38

|

0.44

|

1.38

|

1.19

|

4-0.62

|

2.38

|

0.88

|

0.62

|

0.90

|

0.84

|

0.56

|

1.81

|

0.62

|

0.12

|

0.38

|

0.62

|

|

¾

|

3.88

|

0.44

|

0.50

|

1.69

|

1.50

|

4-0.62

|

2.75

|

1.09

|

0.82

|

1.11

|

1.05

|

0.56

|

2.00

|

0.62

|

0.12

|

0.44

|

0.62

|

|

1

|

4.25

|

0.50

|

0.56

|

2.00

|

1.94

|

4-0.62

|

3.12

|

1.36

|

1.05

|

1.38

|

1.32

|

0.62

|

2.12

|

0.69

|

0.12

|

0.50

|

0.69

|

|

1¼

|

4.62

|

0.56

|

0.62

|

2.50

|

2.31

|

4-0.62

|

3.50

|

1.70

|

1.38

|

1.72

|

1.66

|

0.75

|

2.19

|

0.81

|

0.19

|

0.56

|

0.81

|

|

1½

|

5.00

|

0.62

|

0.69

|

2.88

|

2.56

|

4-0.62

|

3.88

|

1.95

|

1.61

|

1.97

|

1.90

|

0.81

|

2.38

|

0.88

|

0.25

|

0.62

|

0.88

|

|

2

|

6.00

|

0.69

|

0.75

|

3.62

|

3.06

|

4-0.75

|

4.75

|

2.44

|

2.07

|

2.46

|

2.38

|

0.94

|

2.44

|

1.00

|

0.31

|

0.69

|

1.00

|

|

2½

|

7.00

|

0.81

|

0.88

|

4.12

|

3.56

|

4-0.75

|

5.50

|

2.94

|

2.47

|

2.97

|

2.88

|

1.06

|

2.69

|

1.12

|

0.31

|

0.75

|

1.12

|

|

3

|

7.50

|

0.88

|

0.94

|

5.00

|

4.25

|

4-0.75

|

6.00

|

3.57

|

3.07

|

3.60

|

3.50

|

1.12

|

2.69

|

1.19

|

0.38

|

0.81

|

1.19

|

|

3½

|

8.50

|

0.88

|

0.94

|

5.50

|

4.81

|

8-0.75

|

7.00

|

4.07

|

3.55

|

4.10

|

4.00

|

1.19

|

2.75

|

1.25

|

0.38

|

0.88

|

1.25

|

|

4

|

9.00

|

0.88

|

0.94

|

6.19

|

5.31

|

8-0.75

|

7.50

|

4.57

|

4.03

|

4.60

|

4.50

|

1.25

|

2.94

|

1.31

|

0.44

|

0.94

|

1.31

|

|

5

|

10.00

|

0.88

|

0.94

|

7.31

|

6.44

|

8-0.88

|

8.50

|

5.66

|

5.05

|

5.69

|

5.56

|

1.38

|

3.44

|

1.44

|

0.44

|

0.94

|

1.44

|

|

6

|

11.00

|

0.94

|

1.00

|

8.50

|

7.56

|

8-0.88

|

9.50

|

6.72

|

6.07

|

6.75

|

6.63

|

1.50

|

3.44

|

1.56

|

0.50

|

1.06

|

1.56

|

|

8

|

13.50

|

1.06

|

1.12

|

10.62

|

9.69

|

8-0.88

|

11.75

|

8.72

|

7.98

|

8.75

|

8.63

|

1.69

|

3.94

|

1.75

|

0.50

|

1.25

|

1.75

|

|

10

|

16.00

|

1.12

|

1.19

|

12.75

|

12.00

|

12-1.00

|

14.25

|

10.88

|

10.02

|

10.92

|

10.75

|

1.88

|

3.94

|

1.94

|

0.50

|

1.31

|

1.94

|

|

12

|

19.00

|

1.19

|

1.25

|

15.00

|

14.38

|

12-1.00

|

17.00

|

12.88

|

12.00

|

12.92

|

12.75

|

2.12

|

4.44

|

2.19

|

0.50

|

1.56

|

2.19

|

|

14

|

21.00

|

1.31

|

1.38

|

16.25

|

15.75

|

12-1.12

|

18.75

|

14.14

|

13.25

|

14.18

|

14.00

|

2.19

|

4.94

|

3.12

|

0.50

|

1.63

|

2.25

|

|

16

|

23.50

|

1.38

|

1.44

|

18.50

|

18.00

|

16-1.12

|

21.25

|

16.16

|

15.25

|

16.19

|

16.00

|

2.44

|

4.94

|

3.44

|

0.50

|

1.75

|

2.50

|

|

18

|

25.00

|

1.50

|

1.56

|

21.00

|

19.88

|

16-1.25

|

22.75

|

18.18

|

17.25

|

18.20

|

18.00

|

2.62

|

5.44

|

3.81

|

0.50

|

1.94

|

2.69

|

|

20

|

27.50

|

1.62

|

1.69

|

23.00

|

22.00

|

20-1.25

|

25.00

|

20.20

|

19.25

|

20.25

|

20.00

|

2.81

|

5.62

|

4.06

|

0.50

|

2.13

|

2.88

|

|

22

|

29.50

|

1.75

|

1.81

|

25.25

|

24.25

|

20-1.38

|

27.25

|

22.22

|

21.25

|

22.25

|

22.00

|

3.07

|

5.82

|

4.25

|

0.50

|

2.38

|

3.13

|

|

24

|

32.00

|

1.81

|

1.88

|

27.25

|

26.12

|

20-1.38

|

29.50

|

24.25

|

23.25

|

24.25

|

24.00

|

3.19

|

5.94

|

4.38

|

0.50

|

2.50

|

3.25

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 300 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

TJ

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

D

|

Thr

|

|

½

|

3.75

|

0.50

|

0.56

|

1.38

|

1.50

|

4-0.63

|

2.62

|

0.88

|

0.62

|

0.90

|

0.84

|

0.81

|

2.00

|

0.88

|

0.12

|

0.93

|

0.38

|

0.62

|

|

¾

|

4.62

|

0.56

|

0.62

|

1.69

|

1.88

|

4-0.75

|

3.25

|

1.09

|

0.82

|

1.11

|

1.05

|

0.94

|

2.19

|

1.00

|

0.12

|

1.14

|

0.44

|

0.62

|

|

1

|

4.88

|

0.62

|

0.69

|

2.00

|

2.12

|

4-0.75

|

3.50

|

1.36

|

1.05

|

1.38

|

1.32

|

1.00

|

2.38

|

1.06

|

0.12

|

1.41

|

0.50

|

0.69

|

|

1¼

|

5.25

|

0.69

|

0.75

|

2.50

|

2.50

|

4-0.75

|

3.88

|

1.70

|

1.38

|

1.72

|

1.66

|

1.00

|

2.50

|

1.06

|

0.19

|

1.75

|

0.56

|

0.81

|

|

1½

|

6.12

|

0.75

|

0.81

|

2.88

|

2.75

|

4-0.88

|

4.50

|

1.95

|

1.61

|

1.97

|

1.90

|

1.13

|

2.63

|

1.19

|

0.25

|

1.98

|

0.62

|

0.88

|

|

2

|

6.50

|

0.81

|

0.88

|

3.62

|

3.31

|

8-0.75

|

5.00

|

2.44

|

2.07

|

2.46

|

2.38

|

1.25

|

2.69

|

1.31

|

0.31

|

2.50

|

0.69

|

1.12

|

|

2½

|

7.50

|

0.94

|

1.00

|

4.12

|

3.94

|

8-0.88

|

5.88

|

2.94

|

2.47

|

2.97

|

2.88

|

1.44

|

2.94

|

1.50

|

0.31

|

3.00

|

0.75

|

1.25

|

|

3

|

8.25

|

1.06

|

1.12

|

5.00

|

4.62

|

8-0.88

|

6.62

|

3.57

|

3.07

|

3.60

|

3.50

|

1.63

|

3.06

|

1.69

|

0.38

|

3.63

|

0.81

|

1.25

|

|

3½

|

9.00

|

1.12

|

1.19

|

5.50

|

5.25

|

8-0.88

|

7.25

|

4.07

|

3.55

|

4.10

|

4.00

|

1.69

|

3.13

|

1.75

|

0.38

|

4.13

|

….

|

1.44

|

|

4

|

10.00

|

1.19

|

1.25

|

6.19

|

5.75

|

8-0.88

|

7.88

|

4.57

|

4.03

|

4.60

|

4.50

|

1.82

|

3.32

|

1.88

|

0.44

|

4.63

|

….

|

1.44

|

|

5

|

11.00

|

1.31

|

1.38

|

7.31

|

7.00

|

8-0.88

|

9.25

|

5.66

|

5.05

|

5.69

|

5.56

|

1.94

|

3.82

|

2.00

|

0.44

|

5.69

|

….

|

1.69

|

|

6

|

12.50

|

1.38

|

1.44

|

8.50

|

8.12

|

12-0.88

|

10.62

|

6.72

|

6.07

|

6.75

|

6.63

|

2.00

|

3.82

|

2.06

|

0.50

|

6.75

|

….

|

1.81

|

|

8

|

15.00

|

1.56

|

1.62

|

10.62

|

10.25

|

12-1.00

|

13.00

|

8.72

|

7.98

|

8.75

|

8.63

|

2.38

|

4.32

|

2.44

|

0.50

|

8.75

|

….

|

2.00

|

|

10

|

17.50

|

1.81

|

1.88

|

12.75

|

12.62

|

16-1.12

|

15.25

|

10.88

|

10.02

|

10.92

|

10.75

|

2.56

|

4.56

|

3.75

|

0.50

|

10.88

|

….

|

2.19

|

|

12

|

20.50

|

1.94

|

2.00

|

15.00

|

14.75

|

16-1.25

|

17.75

|

12.88

|

12.00

|

12.92

|

12.75

|

2.82

|

5.06

|

4.00

|

0.50

|

12.94

|

….

|

2.38

|

|

14

|

23.00

|

2.06

|

2.12

|

16.25

|

16.75

|

20-1.25

|

20.25

|

14.14

|

13.25

|

14.18

|

14.00

|

2.94

|

5.56

|

4.38

|

0.50

|

14.19

|

….

|

2.50

|

|

16

|

25.50

|

2.19

|

2.25

|

18.50

|

19.00

|

20-1.38

|

22.50

|

16.16

|

15.25

|

16.19

|

16.00

|

3.19

|

5.69

|

4.75

|

0.50

|

16.19

|

….

|

2.69

|

|

18

|

28.00

|

2.31

|

2.38

|

21.00

|

21.00

|

24-1.38

|

24.75

|

18.18

|

17.25

|

18.20

|

18.00

|

3.44

|

6.19

|

5.12

|

0.50

|

18.19

|

….

|

2.75

|

|

20

|

30.50

|

2.44

|

2.50

|

23.00

|

23.12

|

24-1.38

|

27.00

|

20.20

|

19.25

|

20.25

|

20.00

|

3.69

|

6.32

|

5.50

|

0.50

|

20.19

|

….

|

2.88

|

|

22

|

33.00

|

2.57

|

2.63

|

25.25

|

25.25

|

24-1.63

|

29.25

|

22.22

|

21.25

|

22.25

|

22.00

|

3.93

|

6.43

|

5.75

|

0.50

|

22.19

|

….

|

3.13

|

|

24

|

36.00

|

2.69

|

2.75

|

27.25

|

27.62

|

24-1.63

|

32.00

|

24.25

|

23.25

|

24.25

|

24.00

|

4.13

|

6.56

|

6.00

|

0.50

|

24.19

|

….

|

3.25

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 400 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

D

|

Thr

|

|

½

|

3.75

|

0.56

|

1.38

|

1.5

|

4-0.63

|

2.62

|

0.88

|

|

0.9

|

0.84

|

0.88

|

2.06

|

0.88

|

0.12

|

0.93

|

0.38

|

0.62

|

|

¾

|

4.62

|

0.62

|

1.69

|

1.88

|

4-0.75

|

3.25

|

1.09

|

1.11

|

1.05

|

1

|

2.25

|

1

|

0.12

|

1.14

|

0.44

|

0.62

|

|

|

1

|

4.88

|

0.69

|

2

|

2.12

|

4-.075

|

3.5

|

1.36

|

1.38

|

1.32

|

1.06

|

2.44

|

1.06

|

0.12

|

1.41

|

0.5

|

0.69

|

|

|

1¼

|

5.25

|

0.81

|

2.5

|

2.5

|

4-0.75

|

3.88

|

1.7

|

1.72

|

1.66

|

1.12

|

2.62

|

1.12

|

0.19

|

1.75

|

0.56

|

0.81

|

|

|

1½

|

6.12

|

0.88

|

2.88

|

2.75

|

4-0.88

|

4.5

|

1.95

|

1.97

|

1.9

|

1.25

|

2.75

|

1.25

|

0.25

|

1.99

|

0.62

|

0.88

|

|

|

2

|

6.5

|

1

|

3.62

|

3.31

|

8-0.75

|

5

|

2.44

|

2.46

|

2.38

|

1.44

|

2.88

|

1.44

|

0.31

|

2.5

|

0.69

|

1.12

|

|

|

2½

|

7.5

|

1.12

|

4.12

|

3.94

|

8-0.88

|

5.88

|

2.94

|

2.97

|

2.88

|

1.62

|

3.12

|

1.62

|

0.31

|

3

|

0.75

|

1.25

|

|

|

3

|

8.25

|

1.25

|

5

|

4.62

|

8-0.88

|

6.62

|

3.57

|

3.6

|

3.5

|

1.81

|

3.25

|

1.81

|

0.38

|

3.63

|

0.81

|

1.38

|

|

|

3½

|

9

|

1.38

|

5.5

|

5.25

|

8-1.00

|

7.25

|

4.07

|

4.1

|

4

|

1.94

|

3.38

|

1.94

|

0.38

|

4.13

|

….

|

1.56

|

|

|

4

|

10

|

1.38

|

6.19

|

5.75

|

8-1.00

|

7.88

|

4.57

|

4.6

|

4.5

|

2

|

3.5

|

2

|

0.44

|

4.63

|

….

|

1.44

|

|

|

5

|

11

|

1.5

|

7.31

|

7

|

8-1.00

|

9.25

|

5.66

|

5.69

|

5.56

|

2.12

|

4

|

2.12

|

0.44

|

5.69

|

….

|

1.69

|

|

|

6

|

12.5

|

1.62

|

8.5

|

8.12

|

12-1.00

|

10.62

|

6.72

|

6.75

|

6.63

|

2.25

|

4.06

|

2.25

|

0.5

|

6.75

|

….

|

1.81

|

|

|

8

|

15

|

1.88

|

10.62

|

10.25

|

12-1.12

|

13

|

8.72

|

8.75

|

8.63

|

2.69

|

4.62

|

2.69

|

0.5

|

8.75

|

….

|

2

|

|

|

10

|

17.5

|

2.12

|

12.75

|

12.62

|

16-1.25

|

15.25

|

10.88

|

10.92

|

10.75

|

2.88

|

4.88

|

4

|

0.5

|

10.88

|

….

|

2.19

|

|

|

12

|

20.5

|

2.25

|

15

|

14.75

|

16-1.38

|

17.75

|

12.88

|

12.92

|

12.75

|

3.12

|

5.38

|

4.25

|

0.5

|

12.94

|

….

|

2.38

|

|

|

14

|

23

|

2.38

|

16.25

|

16.75

|

20-1.38

|

20.25

|

14.14

|

14.18

|

14

|

3.31

|

5.88

|

4.62

|

0.5

|

14.19

|

….

|

2.5

|

|

|

16

|

25.5

|

2.5

|

18.5

|

19

|

20-1.50

|

22.5

|

16.16

|

16.19

|

16

|

3.69

|

6

|

5

|

0.5

|

16.19

|

….

|

2.69

|

|

|

18

|

28

|

2.62

|

21

|

21

|

24-1.50

|

24.75

|

18.18

|

18.2

|

18

|

3.88

|

6.5

|

5.38

|

0.5

|

18.19

|

….

|

2.75

|

|

|

20

|

30.5

|

2.75

|

23

|

23.12

|

24-1.62

|

27

|

20.2

|

20.25

|

20

|

4

|

6.62

|

5.75

|

0.5

|

20.19

|

….

|

2.88

|

|

|

22

|

33

|

2.88

|

25.25

|

25.25

|

24-1.75

|

29.25

|

22.22

|

22.25

|

22

|

4.25

|

6.75

|

6

|

0.5

|

….

|

….

|

–

|

|

|

24

|

36

|

3

|

27.25

|

27.62

|

24-1.88

|

32

|

24.25

|

24.25

|

24

|

4.5

|

6.88

|

6.25

|

0.5

|

24.19

|

….

|

3.25

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 600 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

D

|

Thr

|

|

½

|

3.75

|

0.56

|

1.38

|

1.5

|

4-0.63

|

2.62

|

0.88

|

0.9

|

0.84

|

0.88

|

2.06

|

0.88

|

0.12

|

0.93

|

0.38

|

0.62

|

|

|

¾

|

4.62

|

0.62

|

1.69

|

1.88

|

4-0.75

|

3.25

|

1.09

|

1.11

|

1.05

|

1

|

2.25

|

1

|

0.12

|

1.14

|

0.44

|

0.62

|

|

|

1

|

4.88

|

0.69

|

2

|

2.12

|

4-0.75

|

3.5

|

1.36

|

1.38

|

1.32

|

1.06

|

2.44

|

1.06

|

0.12

|

1.41

|

0.5

|

0.69

|

|

|

1¼

|

5.25

|

0.81

|

2.5

|

2.5

|

4-0.75

|

3.88

|

1.7

|

1.72

|

1.66

|

1.12

|

2.62

|

1.12

|

0.19

|

1.75

|

0.56

|

0.81

|

|

|

1½

|

6.12

|

0.88

|

2.88

|

2.75

|

4-0.88

|

4.5

|

1.95

|

1.97

|

1.9

|

1.25

|

2.75

|

1.25

|

0.25

|

1.99

|

0.62

|

0.88

|

|

|

2

|

6.5

|

1

|

3.62

|

3.31

|

8-0.75

|

5

|

2.44

|

2.46

|

2.38

|

1.44

|

2.88

|

1.44

|

0.31

|

2.5

|

0.69

|

1.12

|

|

|

2½

|

7.5

|

1.12

|

4.12

|

3.94

|

8-0.88

|

5.88

|

2.94

|

2.97

|

2.88

|

1.62

|

3.12

|

1.62

|

0.31

|

3

|

0.75

|

1.25

|

|

|

3

|

8.25

|

1.25

|

5

|

4.62

|

8-0.88

|

6.62

|

3.57

|

3.6

|

3.5

|

1.81

|

3.25

|

1.81

|

0.38

|

3.63

|

0.81

|

1.38

|

|

|

3½

|

9

|

1.38

|

5.5

|

5.25

|

8-1.00

|

7.25

|

4.07

|

4.1

|

4

|

1.94

|

3.38

|

1.94

|

0.38

|

4.13

|

….

|

1.56

|

|

|

4

|

10.75

|

1.5

|

6.19

|

6

|

8-1.00

|

8.5

|

4.57

|

4.6

|

4.5

|

2.12

|

4

|

2.12

|

0.44

|

4.63

|

….

|

1.62

|

|

|

5

|

13

|

1.75

|

7.31

|

7.44

|

8-1.12

|

10.5

|

5.66

|

5.69

|

5.56

|

2.38

|

4.5

|

2.38

|

0.44

|

5.69

|

….

|

1.88

|

|

|

6

|

14

|

1.88

|

8.5

|

8.75

|

12-1.12

|

11.5

|

6.72

|

6.75

|

6.63

|

2.62

|

4.62

|

2.62

|

0.5

|

6.75

|

….

|

2

|

|

|

8

|

16.5

|

2.19

|

10.62

|

10.75

|

12-1.25

|

13.75

|

8.72

|

8.75

|

8.63

|

3

|

5.25

|

3

|

0.5

|

8.75

|

….

|

2.25

|

|

|

10

|

20

|

2.5

|

12.75

|

13.5

|

16-1.38

|

17

|

10.88

|

10.92

|

10.75

|

3.38

|

6

|

4.38

|

0.5

|

10.88

|

….

|

2.56

|

|

|

12

|

22

|

2.62

|

15

|

15.75

|

20-1.38

|

19.25

|

12.88

|

12.92

|

12.75

|

3.62

|

6.12

|

4.62

|

0.5

|

12.94

|

….

|

2.75

|

|

|

14

|

23.75

|

2.75

|

16.25

|

17

|

20-1.50

|

20.75

|

14.14

|

14.18

|

14

|

3.69

|

6.5

|

5

|

0.5

|

14.19

|

….

|

2.88

|

|

|

16

|

27

|

3

|

18.5

|

19.5

|

20-1.63

|

23.75

|

16.16

|

16.19

|

16

|

4.19

|

7

|

5.5

|

0.5

|

16.19

|

….

|

3.06

|

|

|

18

|

29.25

|

3.25

|

21

|

21.5

|

20-1.75

|

25.75

|

18.18

|

18.2

|

18

|

4.62

|

7.25

|

6

|

0.5

|

18.19

|

….

|

3.12

|

|

|

20

|

32

|

3.5

|

23

|

24

|

24-1.75

|

28.5

|

20.2

|

20.25

|

20

|

5

|

7.5

|

6.5

|

0.5

|

20.19

|

….

|

3.25

|

|

|

22

|

34.25

|

3.75

|

25.25

|

26.25

|

24-1.75

|

30.63

|

22.22

|

22.25

|

22

|

5.25

|

7.75

|

6.88

|

0.5

|

….

|

….

|

–

|

|

|

24

|

37

|

4

|

27.25

|

28.25

|

24-2.00

|

33

|

24.25

|

24.25

|

24

|

5.5

|

8

|

7.25

|

0.5

|

24.19

|

….

|

3.62

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 900 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

Thr

|

|

Sizes 1/2″ through 2 1/2″ are identical to class 1500.

|

||||||||||||||||

|

3

|

9.5

|

1.5

|

5

|

5

|

8-1.00

|

7.5

|

3.57

|

|

3.6

|

3.5

|

2.12

|

4

|

2.12

|

0.38

|

3.63

|

1.62

|

|

4

|

11.5

|

1.75

|

6.19

|

6.25

|

8-1.25

|

9.25

|

4.57

|

4.6

|

4.5

|

2.75

|

4.5

|

2.75

|

0.44

|

4.63

|

1.88

|

|

|

5

|

13.75

|

2

|

7.31

|

7.5

|

8-1.38

|

11

|

5.66

|

5.69

|

5.56

|

3.12

|

5

|

3.12

|

0.44

|

5.69

|

2.12

|

|

|

6

|

15

|

2.19

|

8.5

|

9.25

|

12-1.25

|

12.5

|

6.72

|

6.75

|

6.63

|

3.38

|

5.5

|

3.38

|

0.5

|

6.75

|

2.25

|

|

|

8

|

18.5

|

2.5

|

10.63

|

11.75

|

12-1.50

|

15.5

|

8.72

|

8.75

|

8.63

|

4

|

6.38

|

4.5

|

0.5

|

8.75

|

2.5

|

|

|

10

|

21.5

|

2.75

|

12.75

|

14.5

|

16-1.50

|

18.5

|

10.88

|

10.92

|

10.75

|

4.25

|

7.25

|

5

|

0.5

|

10.88

|

2.81

|

|

|

12

|

24

|

3.12

|

15

|

16.5

|

20-1.50

|

21

|

12.88

|

12.92

|

12.75

|

4.63

|

7.88

|

5.62

|

0.5

|

12.94

|

3

|

|

|

14

|

25.25

|

3.38

|

16.25

|

17.75

|

20-1.63

|

22

|

14.14

|

14.18

|

14

|

5.12

|

8.38

|

6.12

|

0.5

|

14.19

|

3.25

|

|

|

16

|

27.75

|

3.5

|

18.5

|

20

|

20-1.75

|

24.25

|

16.16

|

16.19

|

16

|

5.25

|

8.5

|

6.5

|

0.5

|

16.19

|

3.38

|

|

|

18

|

31

|

4

|

21

|

22.25

|

20-2.00

|

27

|

18.18

|

18.2

|

18

|

6

|

9

|

7.5

|

0.5

|

18.19

|

3.5

|

|

|

20

|

33.75

|

4.25

|

23

|

24.5

|

20-2.13

|

29.5

|

20.2

|

20.25

|

20

|

6.25

|

9.75

|

8.25

|

0.5

|

20.19

|

3.62

|

|

|

24

|

41

|

5.5

|

27.25

|

29.5

|

20-2.63

|

35.5

|

24.25

|

24.25

|

24

|

8

|

11.5

|

10.5

|

0.5

|

24.19

|

4

|

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 1500 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

D

|

Thr

|

|

½

|

4.75

|

0.88

|

1.38

|

1.5

|

4-0.88

|

3.25

|

0.88

|

0.9

|

0.84

|

1.25

|

2.38

|

1.25

|

0.12

|

0.93

|

0.38

|

0.88

|

|

|

¾

|

5.12

|

1

|

1.69

|

1.75

|

4-0.88

|

3.5

|

1.09

|

1.11

|

1.05

|

1.38

|

2.75

|

1.38

|

0.12

|

1.14

|

0.44

|

1

|

|

|

1

|

5.88

|

1.12

|

2

|

2.06

|

4-1.00

|

4

|

1.36

|

1.38

|

1.32

|

1.62

|

2.88

|

1.62

|

0.12

|

1.41

|

0.5

|

1.12

|

|

|

1¼

|

6.25

|

1.12

|

2.5

|

2.5

|

4-1.00

|

4.38

|

1.7

|

1.72

|

1.66

|

1.62

|

2.88

|

1.62

|

0.19

|

1.75

|

0.56

|

1.19

|

|

|

1½

|

7

|

1.25

|

2.88

|

2.75

|

4-1.12

|

4.88

|

1.95

|

1.97

|

1.9

|

1.75

|

3.25

|

1.75

|

0.25

|

1.99

|

0.62

|

1.25

|

|

|

2

|

8.5

|

1.5

|

3.63

|

4.12

|

8-1.00

|

6.5

|

2.44

|

2.46

|

2.38

|

2.25

|

4

|

2.25

|

0.31

|

2.5

|

0.69

|

1.5

|

|

|

2½

|

9.62

|

1.62

|

4.13

|

4.88

|

8-1.12

|

7.5

|

2.94

|

2.97

|

2.88

|

2.5

|

4.12

|

2.5

|

0.31

|

3

|

0.75

|

1.88

|

|

|

3

|

10.5

|

1.88

|

5

|

5.25

|

8-1.25

|

8

|

….

|

3.6

|

3.5

|

….

|

4.62

|

2.88

|

0.38

|

….

|

….

|

….

|

|

|

4

|

12.25

|

2.12

|

6.19

|

6.38

|

8-1.38

|

9.5

|

….

|

4.6

|

4.5

|

….

|

4.88

|

3.56

|

0.44

|

….

|

….

|

….

|

|

|

5

|

14.75

|

2.88

|

7.31

|

7.75

|

8-1.63

|

11.5

|

….

|

5.69

|

5.56

|

….

|

6.12

|

4.12

|

0.44

|

….

|

….

|

….

|

|

|

6

|

15.5

|

3.25

|

8.5

|

9

|

12-1.50

|

12.5

|

….

|

6.75

|

6.63

|

….

|

6.75

|

4.69

|

0.5

|

….

|

….

|

….

|

|

|

8

|

19

|

3.62

|

10.63

|

11.5

|

12-1.75

|

15.5

|

….

|

8.75

|

8.63

|

….

|

8.38

|

5.62

|

0.5

|

….

|

….

|

….

|

|

|

10

|

23

|

4.25

|

12.75

|

14.5

|

12-2.00

|

19

|

….

|

10.92

|

10.75

|

….

|

10

|

7

|

0.5

|

….

|

….

|

….

|

|

|

12

|

26.5

|

4.88

|

15

|

17.75

|

16-2.12

|

22.5

|

….

|

12.92

|

12.75

|

….

|

11.12

|

8.62

|

0.5

|

….

|

….

|

….

|

|

|

14

|

29.5

|

5.25

|

16.25

|

19.5

|

16-2.38

|

25

|

….

|

14.18

|

14

|

….

|

11.75

|

9.5

|

0.5

|

….

|

….

|

….

|

|

|

16

|

32.5

|

5.75

|

18.5

|

21.75

|

16-2.63

|

27.75

|

….

|

16.19

|

16

|

….

|

12.25

|

10.25

|

0.5

|

….

|

….

|

….

|

|

|

18

|

36

|

6.38

|

21

|

23.5

|

16-2.88

|

30.5

|

….

|

18.2

|

18

|

….

|

12.88

|

10.88

|

0.5

|

….

|

….

|

….

|

|

|

20

|

38.75

|

7

|

23

|

25.25

|

16-3.12

|

32.75

|

….

|

20.25

|

20

|

….

|

14

|

11.5

|

0.5

|

….

|

….

|

….

|

|

|

24

|

46

|

8

|

27.25

|

30

|

16-3.63

|

39

|

….

|

24.25

|

24

|

….

|

16

|

13

|

0.5

|

….

|

….

|

….

|

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

Ansi B16.5 Class 2500 Forged Flanges

|

Nom. Pipe Size

|

O

|

T

|

R

|

X

|

#/Dia of Holesa

|

Bolt Circle Dia

|

B2b

|

B3

|

H

|

L

|

L2

|

L3c

|

r

|

C

|

Thr

|

|

½

|

5.25

|

1.19

|

1.38

|

1.69

|

4-0.88

|

3.5

|

|

0.9

|

0.84

|

1.56

|

2.88

|

1.56

|

0.12

|

0.93

|

1.12

|

|

¾

|

5.5

|

1.25

|

1.69

|

2

|

4-0.88

|

3.75

|

1.11

|

1.05

|

1.69

|

3.12

|

1.69

|

0.12

|

1.14

|

1.25

|

|

|

1

|

6.25

|

1.38

|

2

|

2.25

|

4-1.00

|

4.25

|

1.38

|

1.32

|

1.88

|

3.5

|

1.88

|

0.12

|

1.41

|

1.38

|

|

|

1¼

|

7.25

|

1.5

|

2.5

|

2.88

|

4-1.12

|

5.13

|

1.72

|

1.66

|

2.06

|

3.75

|

2.06

|

0.19

|

1.75

|

1.5

|

|

|

1½

|

8

|

1.75

|

2.88

|

3.12

|

4-1.25

|

5.75

|

1.97

|

1.9

|

2.38

|

4.38

|

2.38

|

0.25

|

1.99

|

1.75

|

|

|

2

|

9.25

|

2

|

3.63

|

3.75

|

8-1.12

|

6.75

|

2.46

|

2.38

|

2.75

|

5

|

2.75

|

0.31

|

2.5

|

2

|

|

|

2½

|

10.5

|

2.25

|

4.13

|

4.5

|

8-1.25

|

7.75

|

2.97

|

2.88

|

3.12

|

5.62

|

3.12

|

0.31

|

3

|

2.25

|

|

|

3

|

12

|

2.62

|

5

|

5.25

|

8-1.38

|

9

|

3.6

|

3.5

|

….

|

6.62

|

3.62

|

0.38

|

….

|

….

|

|

|

4

|

14

|

3

|

6.19

|

6.5

|

8-1.63

|

10.75

|

4.6

|

4.5

|

….

|

7.5

|

4.25

|

0.44

|

….

|

….

|

|

|

5

|

16.5

|

3.62

|

7.31

|

8

|

8-1.88

|

12.75

|

5.69

|

5.56

|

….

|

9

|

5.12

|

0.44

|

….

|

….

|

|

|

6

|

19

|

4.25

|

8.5

|

9.25

|

8-2.12

|

14.5

|

6.75

|

6.63

|

….

|

10.75

|

6

|

0.5

|

….

|

….

|

|

|

8

|

21.75

|

5

|

10.63

|

12

|

12-2.12

|

17.25

|

8.75

|

8.63

|

….

|

12.5

|

7

|

0.5

|

….

|

….

|

|

|

10

|

26.5

|

6.5

|

12.75

|

14.75

|

12-2.63

|

21.25

|

10.92

|

10.75

|

….

|

16.5

|

9

|

0.5

|

….

|

….

|

|

|

12

|

30

|

7.25

|

15

|

17.38

|

12-2.88

|

24.38

|

12.92

|

12.75

|

….

|

18.25

|

10

|

0.5

|

….

|

….

|

(a)- Bolt hole diameter 1/8 in. larger than bolt diameter.

(b)- Standard bore dimensions provided. See bore chart for other wall thicknesses.

(c)- This dimension is commonly associated with “true” lap joints. Industry standard is to make to the slip on length through the hub.

We Stock All Different Types Of Forged Flanges

|

|

|

EN/PED Steel Flanges

|

|

BS Steel Flanges

|

|

JIS Steel Flanges

|

|

Forged Flanges Marking & Packaging

Forged Flanges are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All Alloy Steel Pipe Fittings and flanges are marked with Grade,

Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our Alloy Steel Pipe Fittings

Stavanger Stal emphasis on the packaging to ensure that there is no damage

during transit the Forged Flanges are packed in wooden corrugated boxes foiled in bubble wraps & are marked with Grade, Lot No, Size, Degree and Stavanger Stal Brand Mark. You can also contact us for customized marking.

Forged Flanges Quality Assurance

At Stavanger Stal, all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Forged Flanges Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

Stavanger Stal offer its Products with Third Party Inspection

also. The Inspection Agency can be nominated by clients or Stavanger Stal can be arrange the TPI by World reputed Agencies like Bureau Veritas, DNV, LLOYDS, ICB and many other. Forged Flanges are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. All our Forged Flanges are manufactured with tested raw materials and are supplied with NABL approved lab test reports. On demand,

we can also provide, Hydro Testing Reports, Non Destructive Test Reports, or Destructive Test Reports.